The Roulunds Roflex v-belts in general are well known for their versatility. The way they are designed with a core of natural rubber blended with power-transmitting tensile strands means that they can be adapted to the vast majority of industrial belt purposes. Roulunds’ belts are also fabric wrapped to protect them from external influences such as heat, oil and even dust particles. The fabric wrapping also helps prevent friction occurring at the points of contact between the belt and the pulley.

With very high cost effectiveness thanks to the high power transmission and relatively low price, the Roulunds variable speed belts are often equipped wherever an industrial machine requires a non-positive drive.

Roulunds Roflex-Vari Industrial Transmission Belts

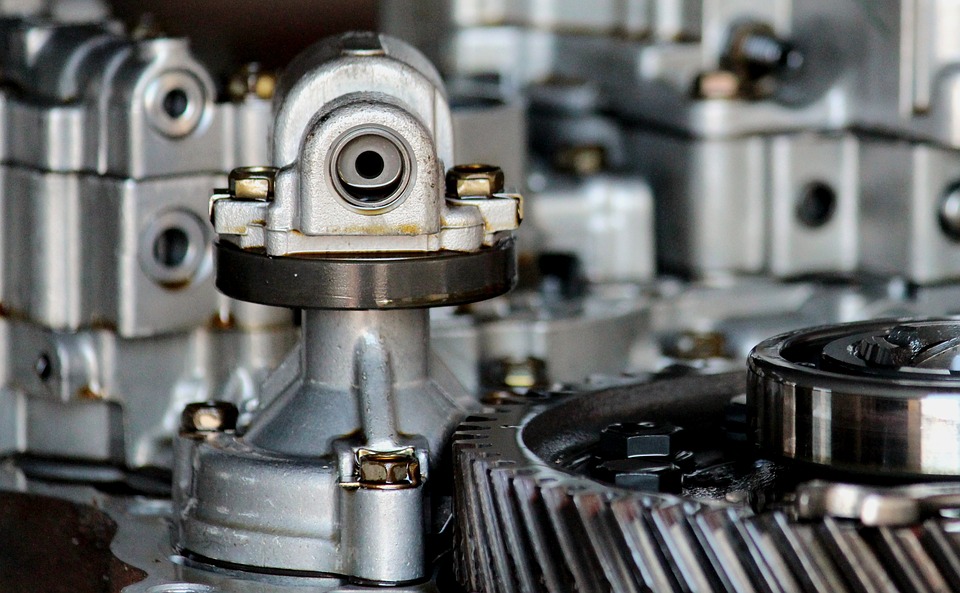

The Roulunds Roflex Vari belt has been developed especially for heavy-duty variator drives, including the famous Variomatic Drive designed by the Dutch automobile manufacturer, DAF Trucks NV. As a variable speed belt that is particularly shock resistant, the Roulunds Roflex-Vari belt can handle loads and impacts that ordinary vari-belts cannot. The trademarked Roflex material also ensures that the Roulunds v-belts are resistant to all surface pressure on their sides, which has been a particular problem suffered by inferior v-belt designs.

Another clever design feature of the Roulunds Roflex-Vari is the controlled slip which allows the belt to automatically act like a clutch belt if there should happen to be an accidental overload.

The Different Tensile Strands of Roulunds Roflex Vari-Belts

There are actually two different kinds of Roulunds Roflex-Vari speed belts, both of which are used for high-power transmission in variable-speed drives. Both variations feature a special rubber compound which is embedded with transverse textile fibres to increase the tensile strength of the belts. This increase in strength produces a highly stable performance and a huge reduction in cross-sectional distortion. The specially moulded toothing of the Roulunds Roflex Vari-belts also helps promote maximum flexibility as well as being a perfect fit for the pulley grooves.

The difference between the two varieties is the tensile strands within the rubber compound. One variation of the belt features tensile strands composed of polyester while the other variation features tensile strands composed of aramid.

Polyester is the more commonly known material and is well known to be extremely strong, especially in fibre form. Aramid is less well known but is a type of synthetic polyamide that is formed from aromatic monomers, although if that is a little too scientific then it simply means that aramid fibres are exceptionally strong. Also, both polyester and aramid are thermally stable which allows the Roulunds Roflex-Vari belts to be used in more extreme temperatures than ordinary variable speed belts are able to withstand.

Properties and Specifications

These variable speed belts can operate in any temperatures ranging between 30°C and 90°C, thus they are suitable for tropical climates. As mentioned before, they are also moderately oil-resistant as well as electrically conductive to ISO 1813. There is also a wide range of profiles and inside lengths to choose from, making these v-belts suitable for most Variator and Variomatic drives.

If you require any Roulunds Roflex-Vari industrial transmission belts, then contact YB Components who can ship these parts all over the UK and the world.