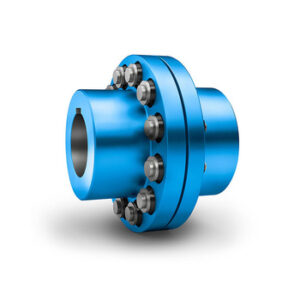

Industrial couplings are crucial elements of a wide range of machinery, so they must be chosen, installed, and maintained correctly to maximise their performance. Here we list some of the most common mistakes made with couplings, and advise on how you can avoid them.

Industrial couplings are crucial elements of a wide range of machinery, so they must be chosen, installed, and maintained correctly to maximise their performance. Here we list some of the most common mistakes made with couplings, and advise on how you can avoid them.

Using an Incorrect Coupling

Installing the wrong kind of coupling can be very expensive as it can cause a lot of different problems. Essential specs to consider include shaft size, torque and the RPM rating, as well as the designated operating conditions and tolerances each coupling is designed for.

A lot of the problems arising from incorrect coupling use are because of generic couplings, which are an inexpensive option but usually cannot produce the necessary performance of a specially designed coupling. A reliable couplings supplier like Yorkshire’s YB Components can advise you on the correct coupling choice.

Delaying Coupling Selection

This mistake is for engineers designing and assembling machinery. It is important to identify the type of coupling you will be using early on in the process. Leaving it late can reduce its performance as well as limit the ways in which the coupling can be used in the system.

Installing Couplings Incorrectly

A pretty obvious one but still worth adding to the list as it is important to follow the manufacturer installation instructions when installing a coupling. Poor installation will lead to premature wear and tear and ultimately the failure of the coupling.

Ignoring Misalignment

Coupling misalignment creates unnecessary stress on multiple machinery components, so it should never be ignored even if the application appears to be operating as normal. Sometimes coupling misalignment can happen as a natural part of the operation, in which case you should always use an appropriate coupling that has been designed to cope with misalignment. Speak to an industry expert such as those at coupling suppliers YB Components to identify a misalignment-compensating coupling.

Exceeding the Recommended RPM

Each coupling will have a recommended RPM rating which you must adhere to. The manufacturer should specify the coupling’s RPM rating, and you should also know what your application’s maximum RPM is to make sure to only use couplings that can match it.

Lack of Regular Maintenance

Wear and tear eventually affect all components in every application in one way or another, but regular maintenance can ensure you get the maximum possible lifespan out of your couplings. Suppliers like Yorkshire’s YB Components will recommend devising a maintenance schedule that keeps the couplings and other components in optimal condition for as long as possible. Such regular maintenance will also keep you informed as to when such components need replacing. This will help prevent running an application into the ground, possibly resulting in costly downtime for repairs.

If you require any couplings, then contact YB Components who are the UK’s leading industrial coupling suppliers in Yorkshire who ship out fast and free all over the UK and the rest of the world.